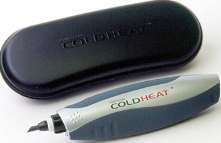

Cold Heat soldering iron

Soldering is fun. With a $10 tool, you can melt little blobs of metal and bond wires together. It's an incredibly useful technique for many small-scale hobby projects, such as modifying my old AAA-battery-powered Earthmate GPS receiver to draw its power from a USB cable instead. (That worked nicely.)

But soldering well is difficult. Amateurs (like me, I'm terrible at it) generally solder the way it makes sense: melt the solder with the iron, then dab it onto the metal. But this doesn't work very well - the result is usually a poorly-placed solder blob barely sitting on some wires, forming a large joint that falls apart easily. The correct technique, which results in stronger, smaller, more precise joints, is to use the iron to heat the items being bonded, then add a bit of solder so that it melts on contact. Simply put, "Heat the work, not the solder."

This is a huge pain, because you have to sit there and hold the iron on a sensitive component for a little while so it can heat up to the solder-melting temperature. This makes computer nerds nervous, since we don't want to burn anything expensive. Plus, you have to wait a while for the iron to heat up before you start using it, and it's always a bit unsettling to have a hot iron sitting around for a while after you're done, waiting to be knocked over.

Apparently, it works by shorting out its own batteries in small increments. Short circuits generate a lot of immediate heat. The soldering tip is made from a material that loses heat quickly, so when you release the button, all of the heat dissipates in a few seconds. The commercial makes the cold-hot-cold transitions look instantaneous. Soldering is finally easy... assuming that the Cold Heat works as advertised.

Of course, it doesn't.

In reality, it doesn't heat the work enough to melt the solder onto it, it's incredibly difficult even to melt the solder directly with the iron, it's still warm after you're done, and the white LED turns itself off while you're actually soldering (right when it would be most useful).

I followed all of the instructions and couldn't make a single joint in a half hour. I could occasionally melt a tiny bit of solder directly, but even that was rare. Bits of the soldering tip even chipped off a few times under normal conditions (not banging it against the wall, although that would have been more satisfying).